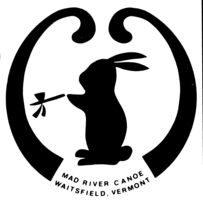

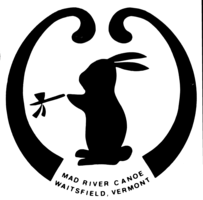

Mad River Canoe Logo

By Ben Nitkin on

I'm working on restoring a Mad River Canoe Adventurer and wanted to reproduce the original logo. It's hard to find online, and the new logo drops the Waitsfield, VT lettering. This fellow on Reddit had some good restoration pics, and I cleaned up a monochrome logo from that.

This should be suitable for printing at any old vinyl sticker company, and it should be easy to invert or colorize to suit. I've uploaded a transparent and a B&W version of the same thing.

https://www.reddit.com/r/canoeing/comments/12qn0io/mad_river_restoration/

T

T